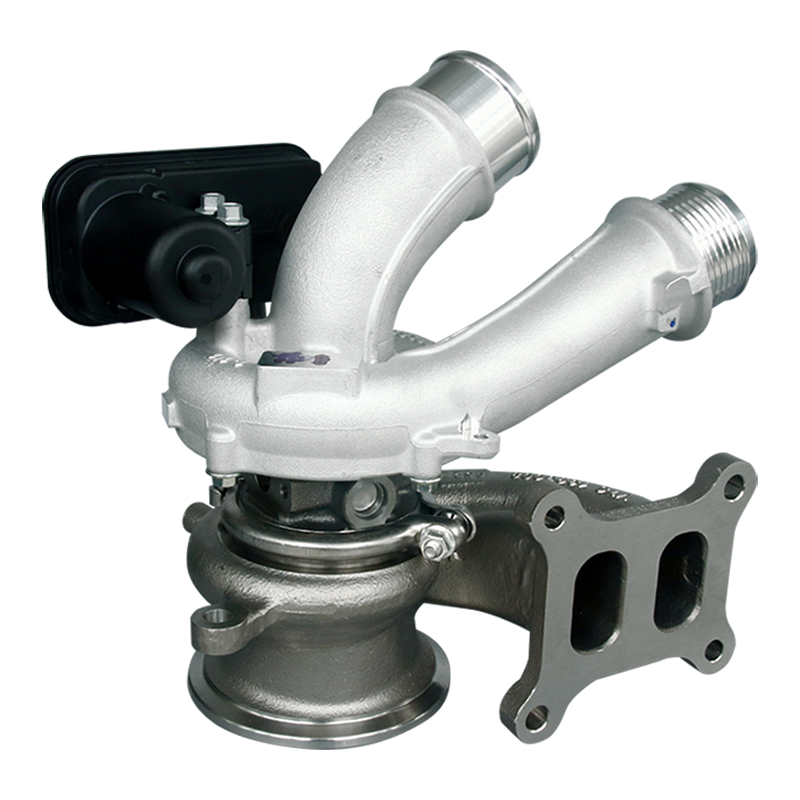

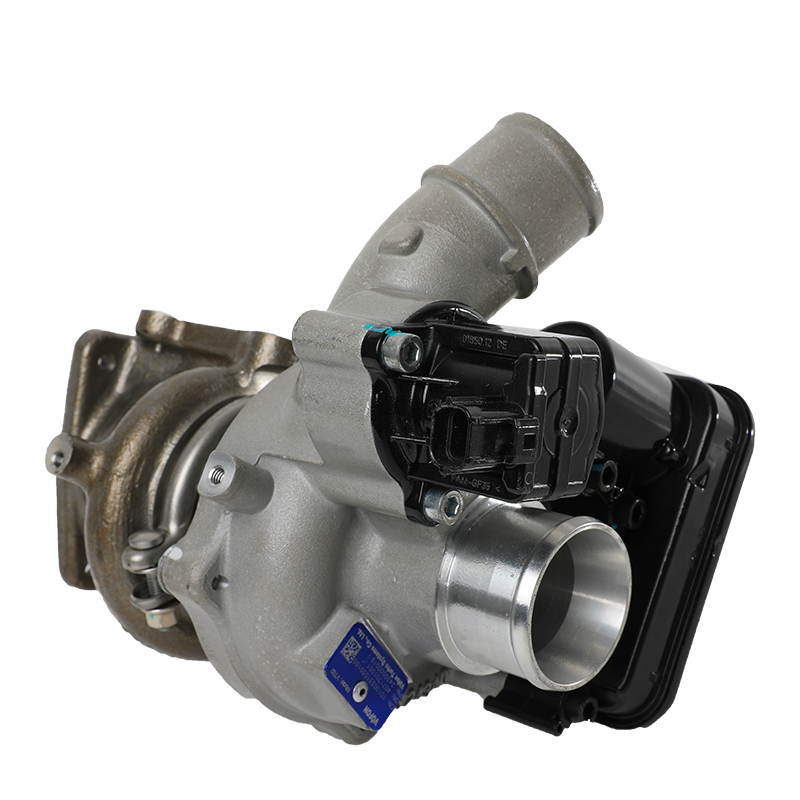

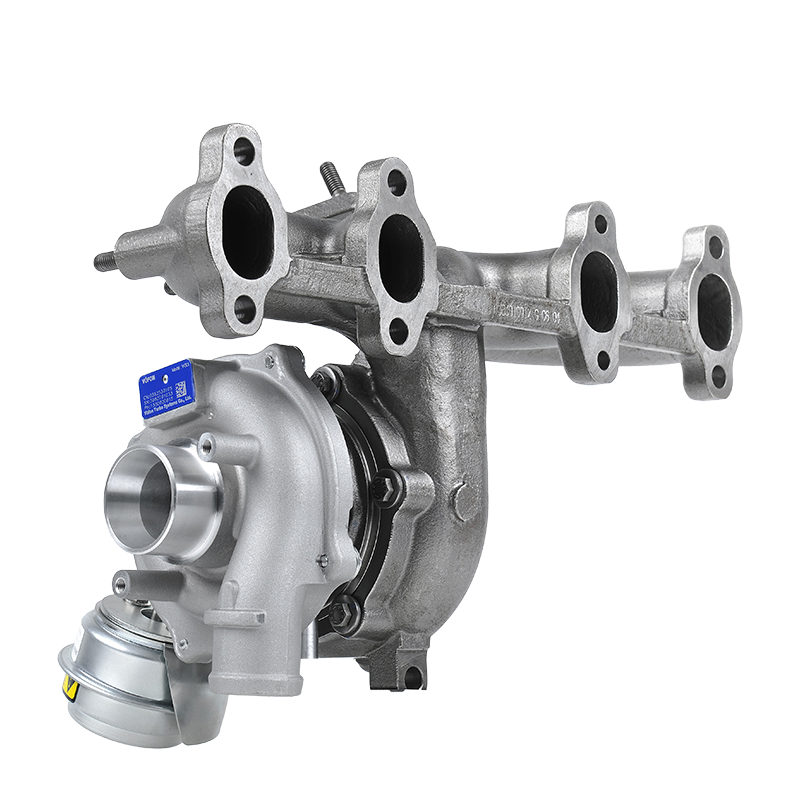

VT01

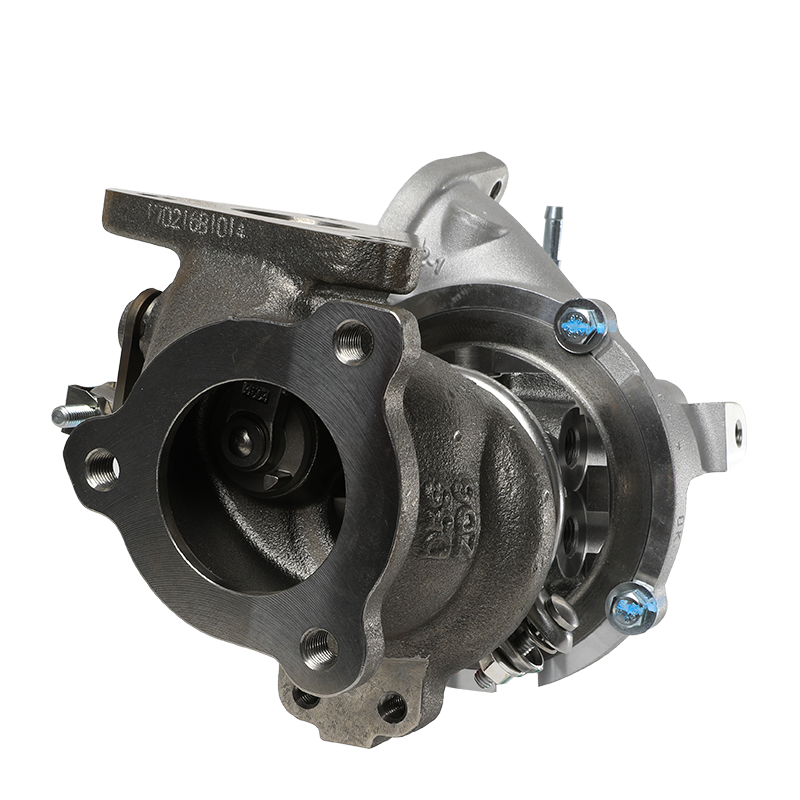

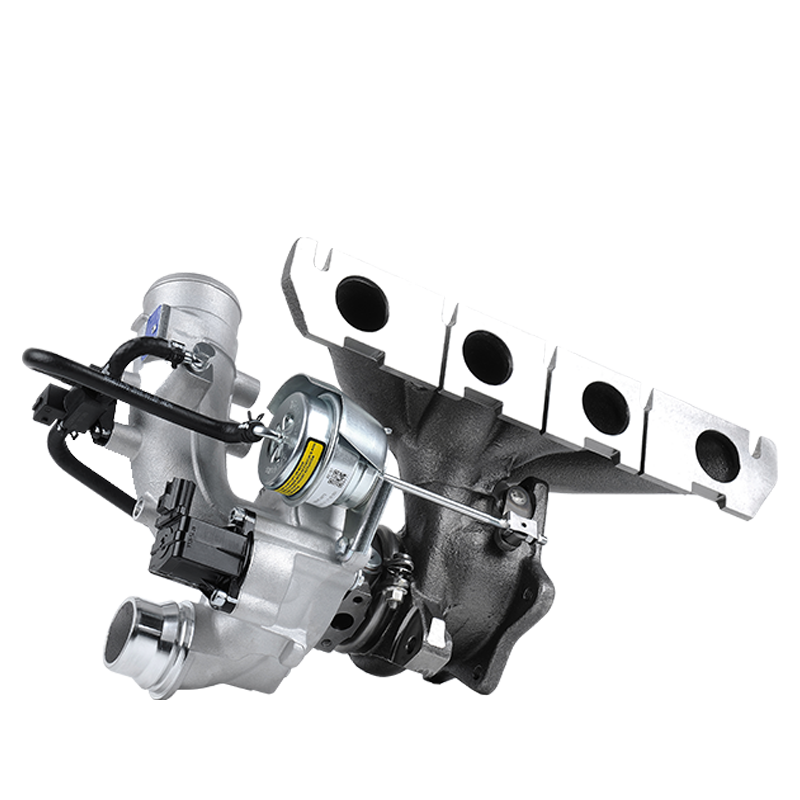

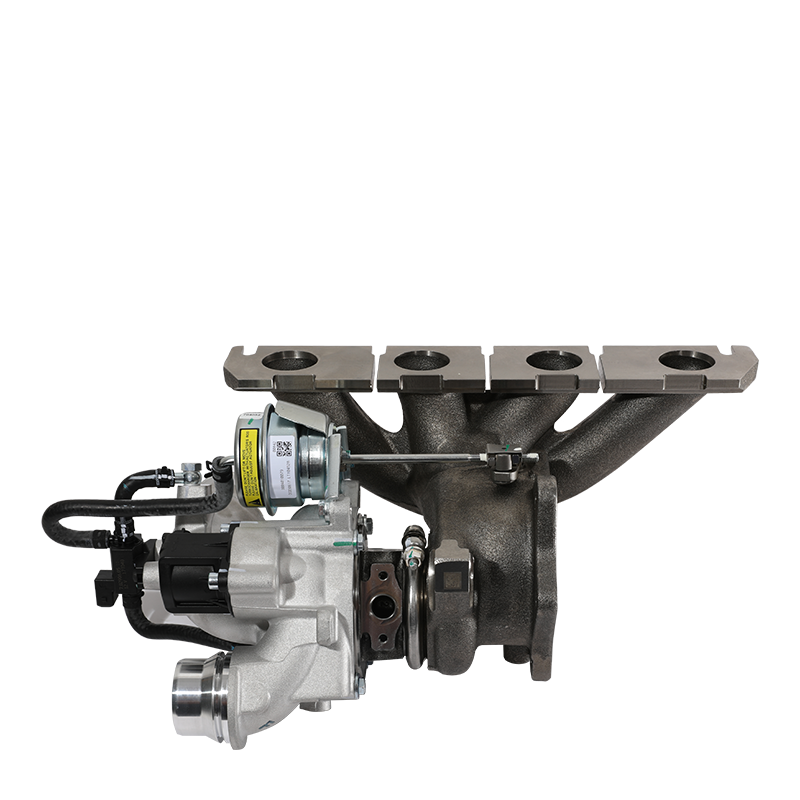

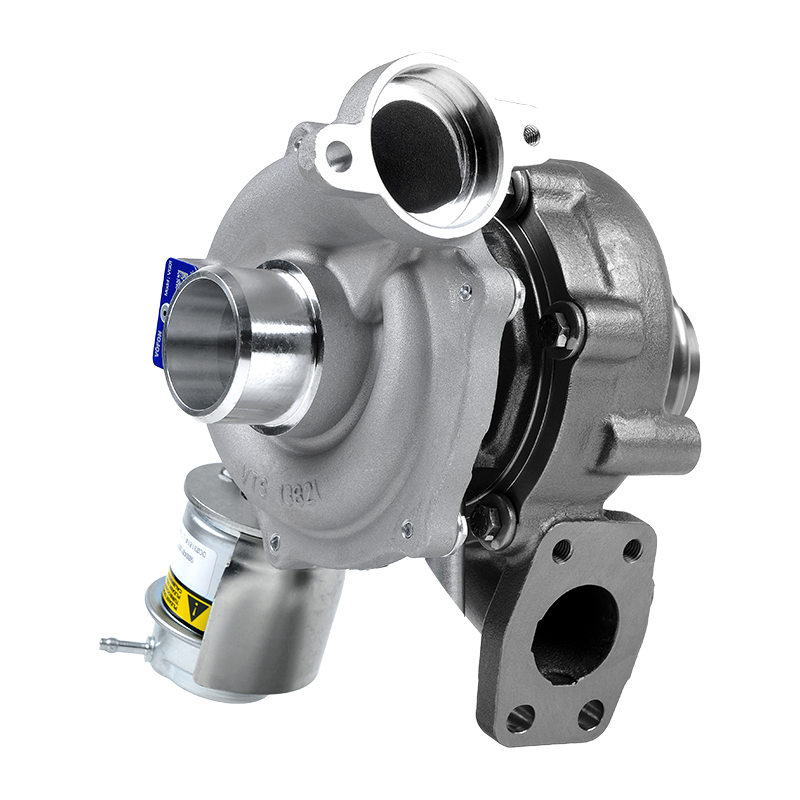

Compact bearing system design

It can meet the customer application requirements of CW and CCW at the same time

Milled or cast impeller optional

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.2L~1.6L National VI B development requirements

Compact bearing system design

It can meet the customer application requirements of CW and CCW at the same time

Milled or cast impeller optional

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.2L~1.6L National VI B development requirements

Compact bearing system design

It can meet the customer application requirements of CW and CCW at the same time

Milled or cast impeller optional

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.2L~1.6L National VI B development requirements

Compact bearing system design

It can meet the customer application requirements of CW and CCW at the same time

Milled or cast impeller optional

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.2L~1.6L National VI B development requirements

Compact bearing system design

It can meet the customer application requirements of CW and CCW at the same time

Milled or cast impeller optional

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.2L~1.6L National VI B development requirements

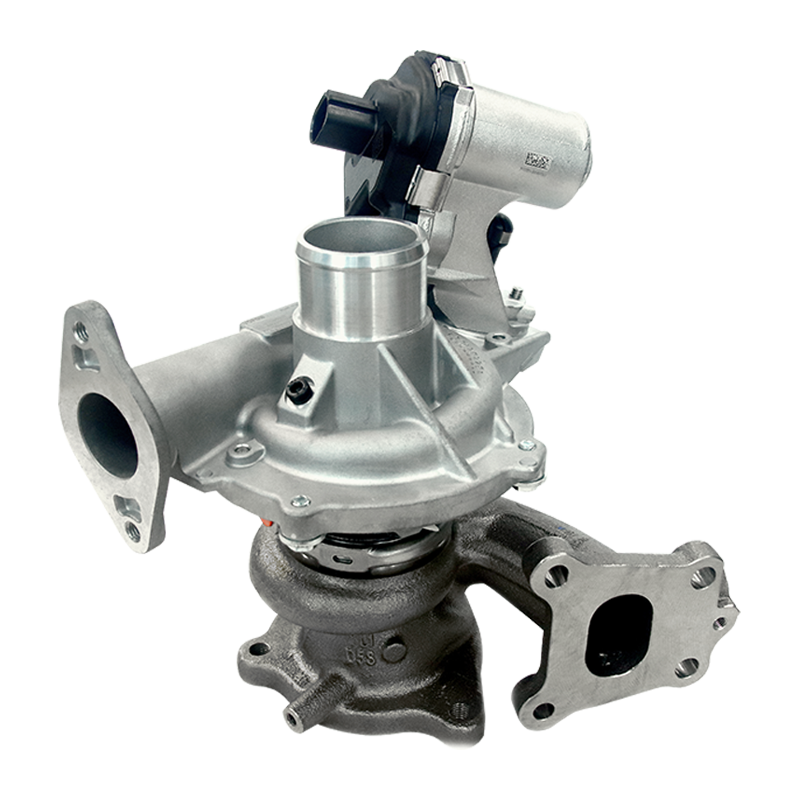

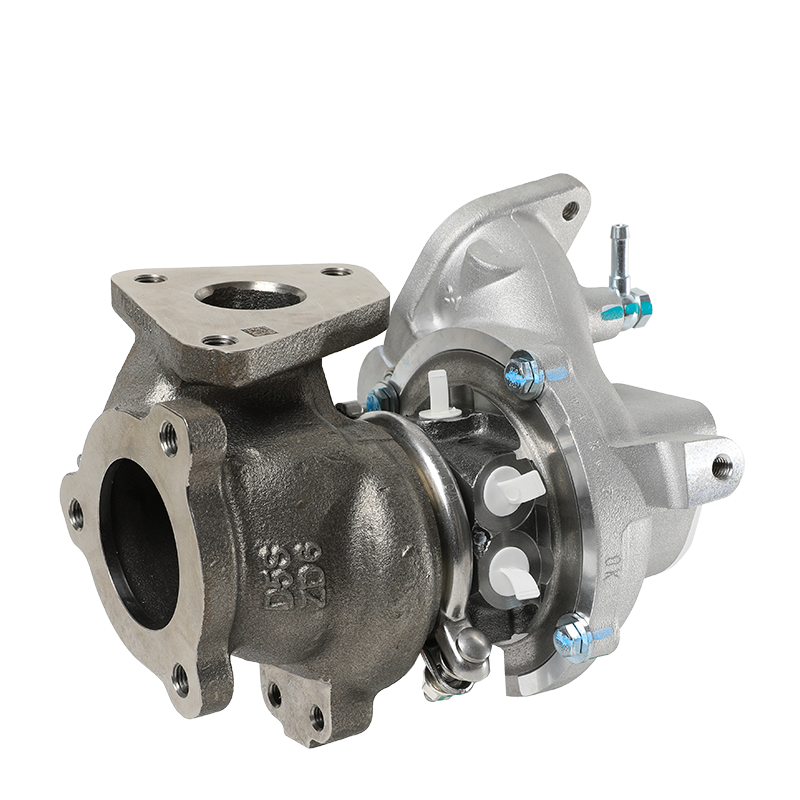

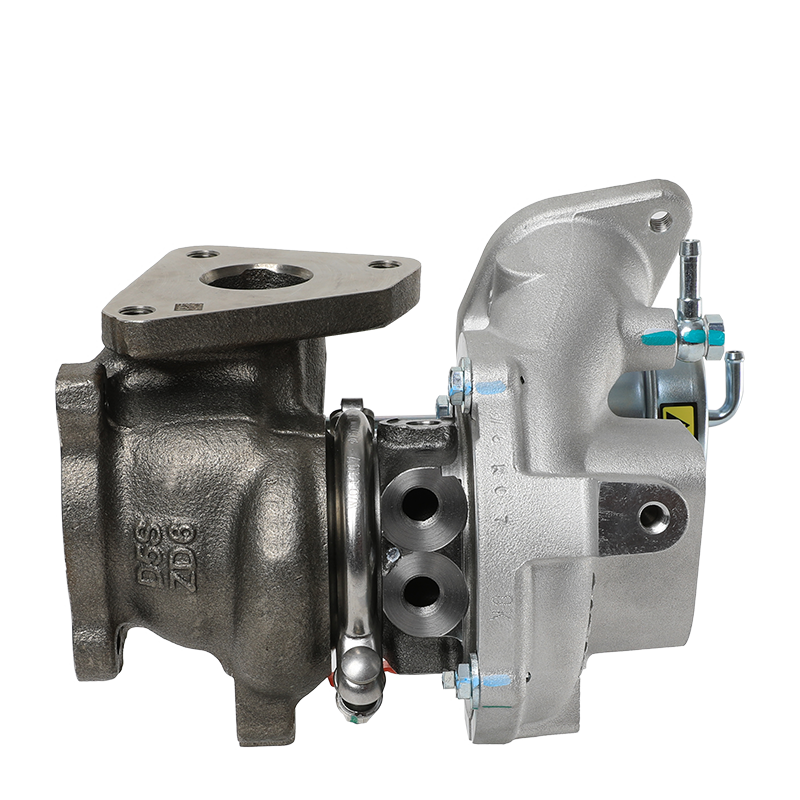

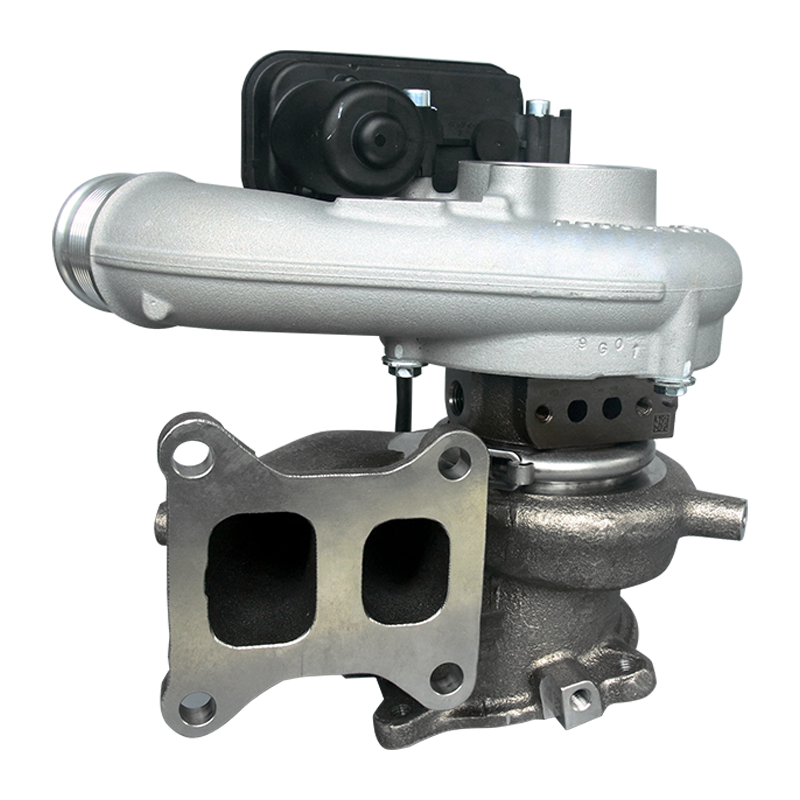

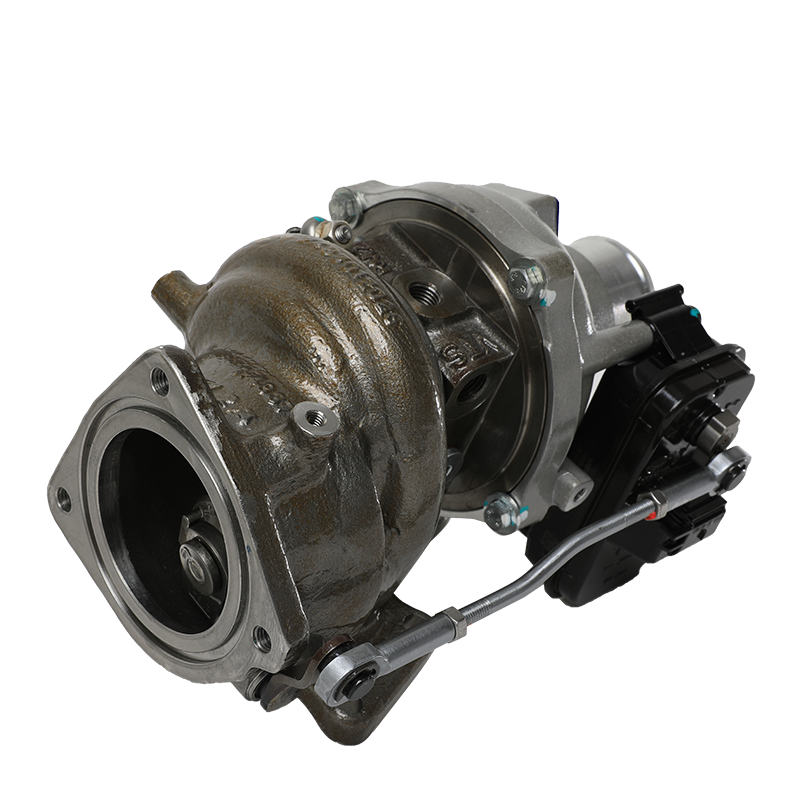

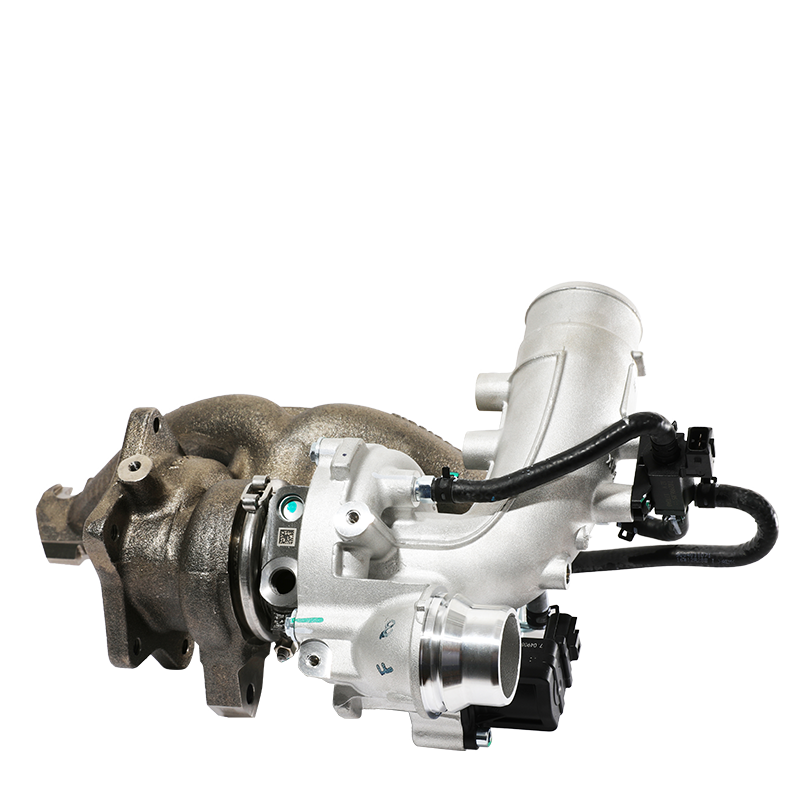

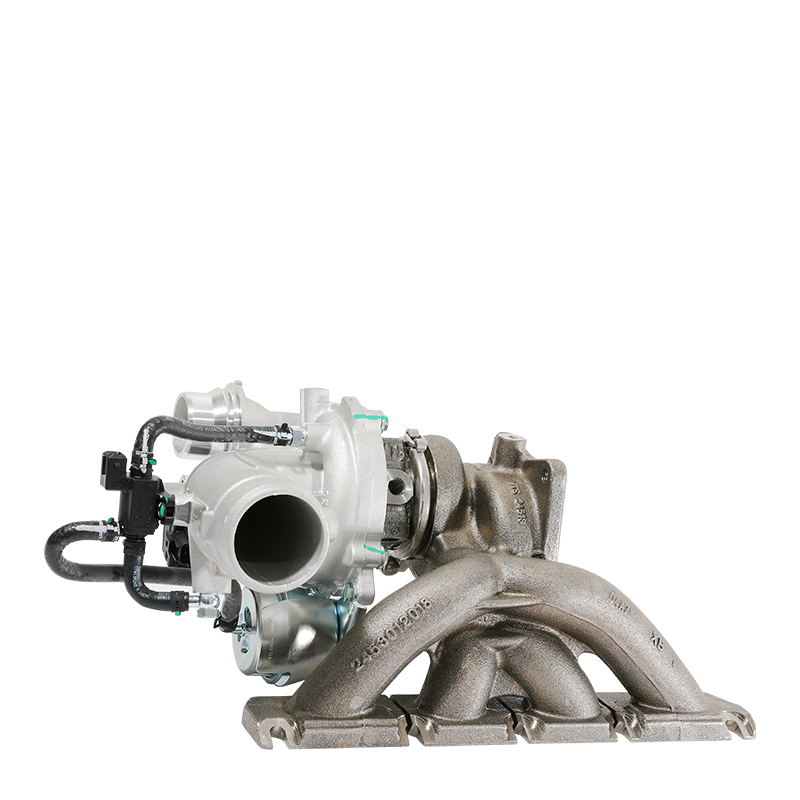

VT02

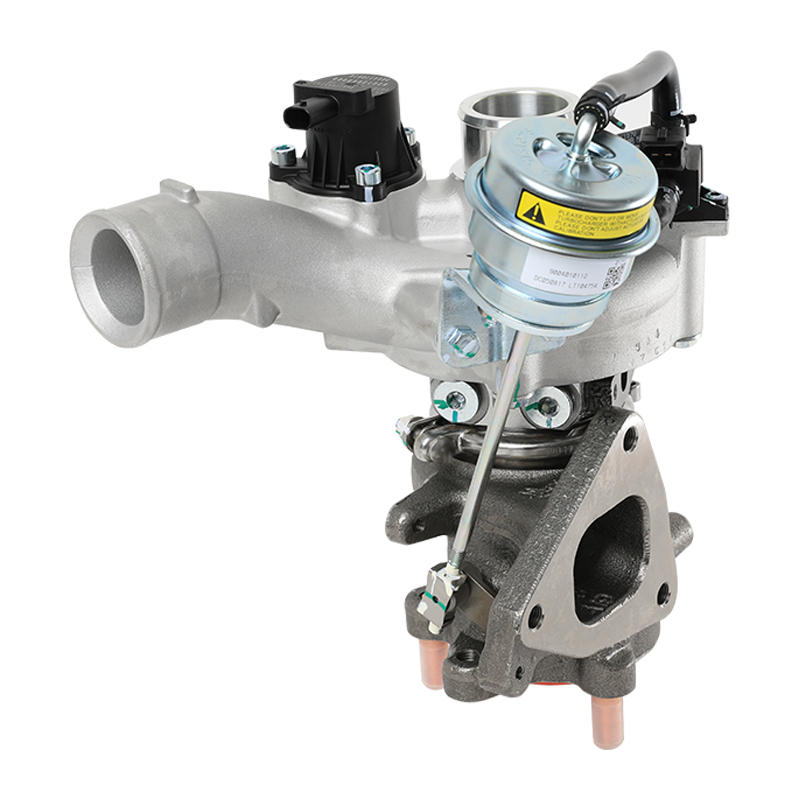

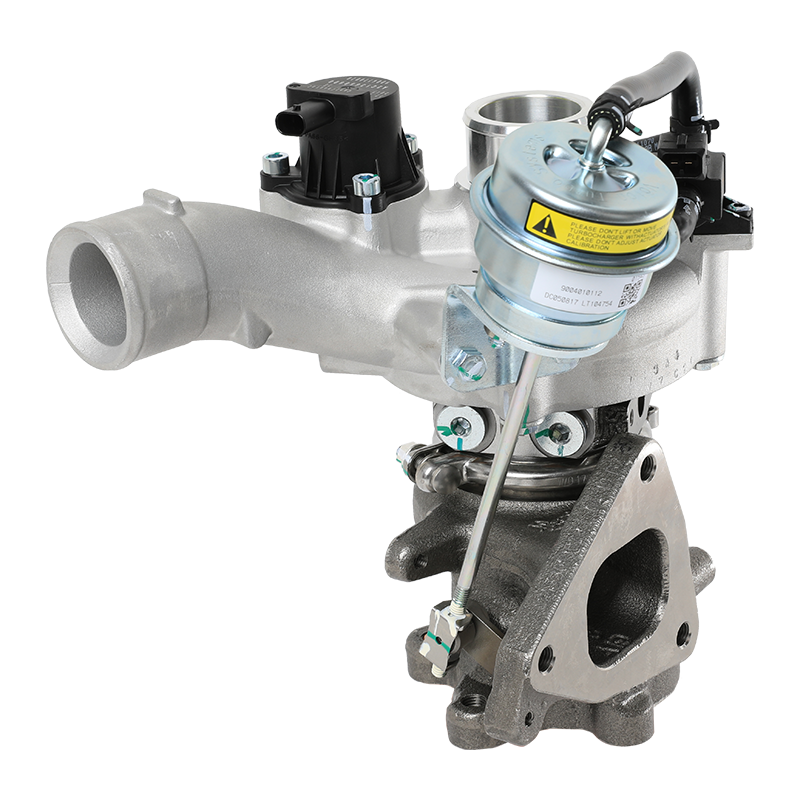

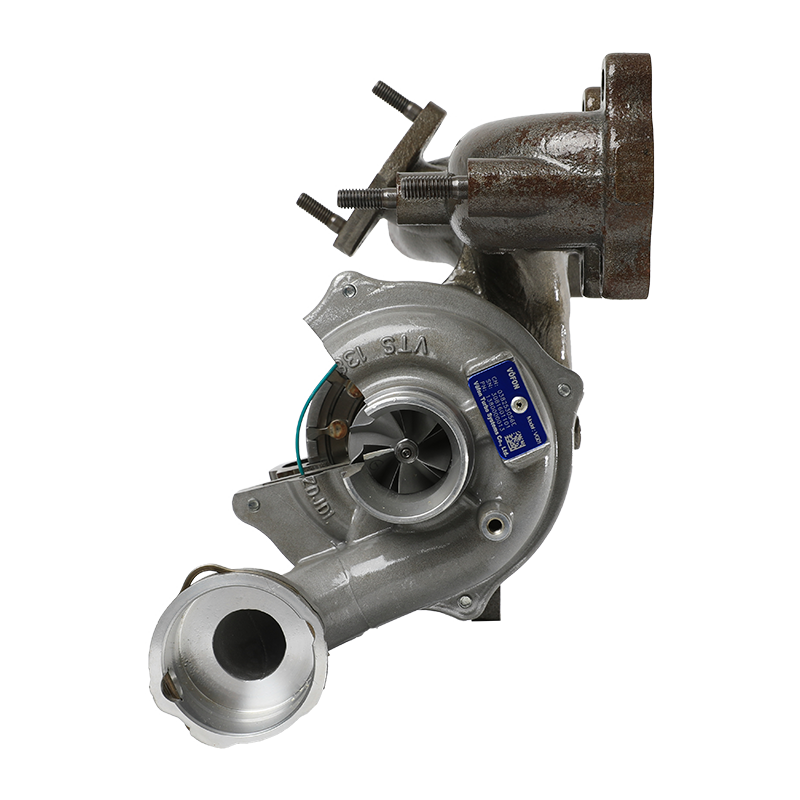

Compact bearing system design

Stronger axial load capacity

Application of Twinscroll (double channel) technology

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.6L~2.0L National VI B development requirements

Compact bearing system design

Stronger axial load capacity

Application of Twinscroll (double channel) technology

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.6L~2.0L National VI B development requirements

Compact bearing system design

Stronger axial load capacity

Application of Twinscroll (double channel) technology

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.6L~2.0L National VI B development requirements

Compact bearing system design

Stronger axial load capacity

Application of Twinscroll (double channel) technology

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.6L~2.0L National VI B development requirements

Compact bearing system design

Stronger axial load capacity

Application of Twinscroll (double channel) technology

Electric actuator and mechanical actuator are optional

The exhaust temperature of the volute can meet Max980℃

Compressor and turbine performance optimization, meeting the 1.6L~2.0L National VI B development requirements

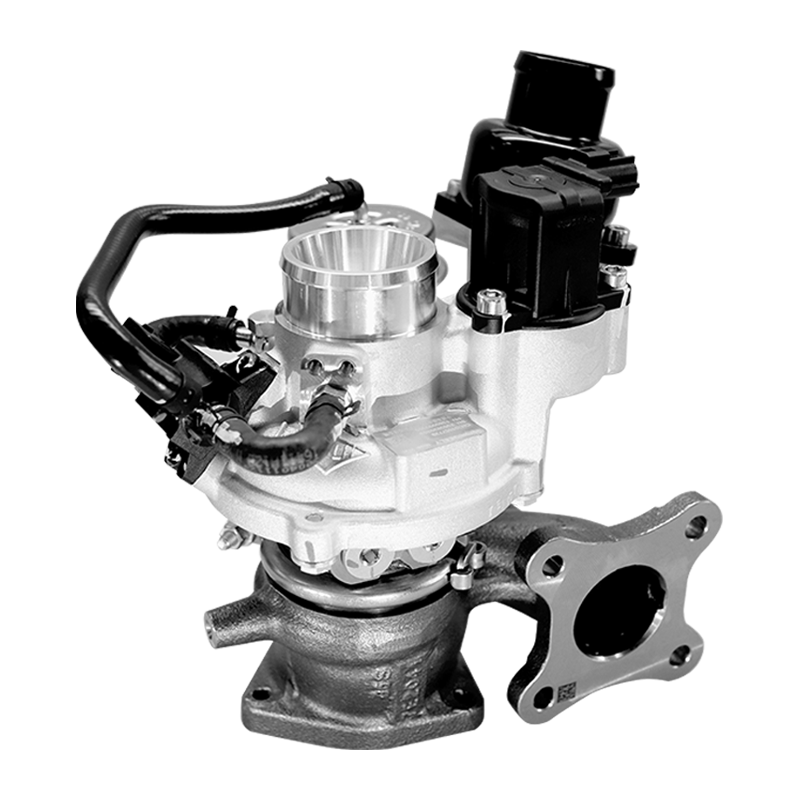

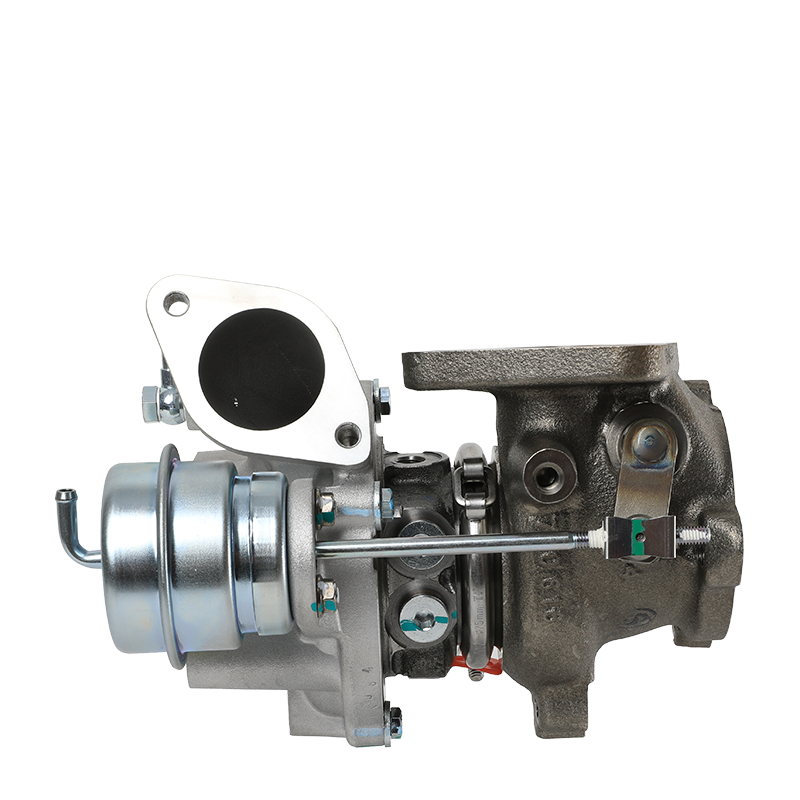

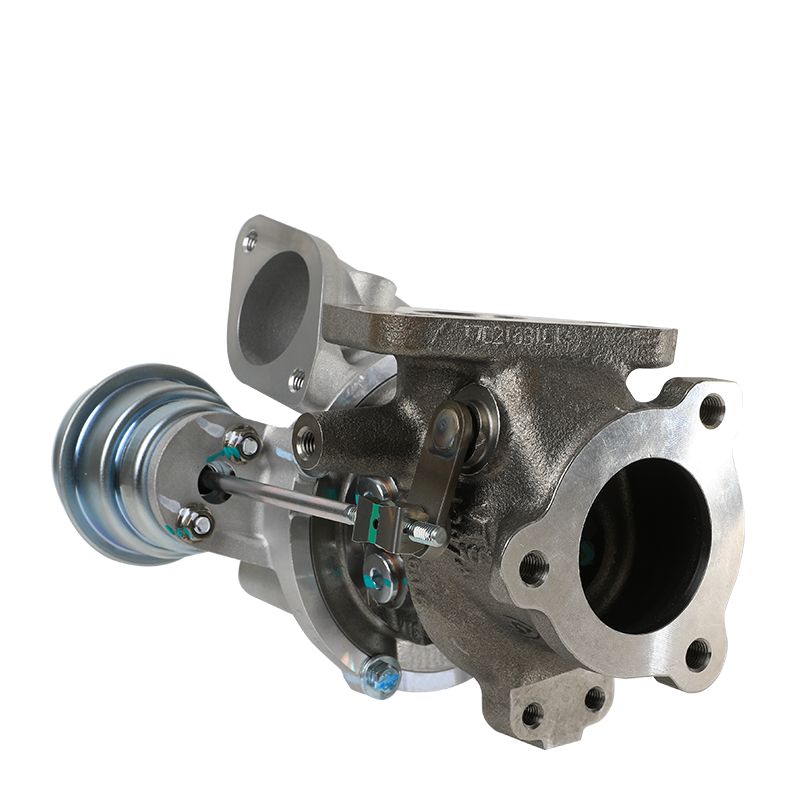

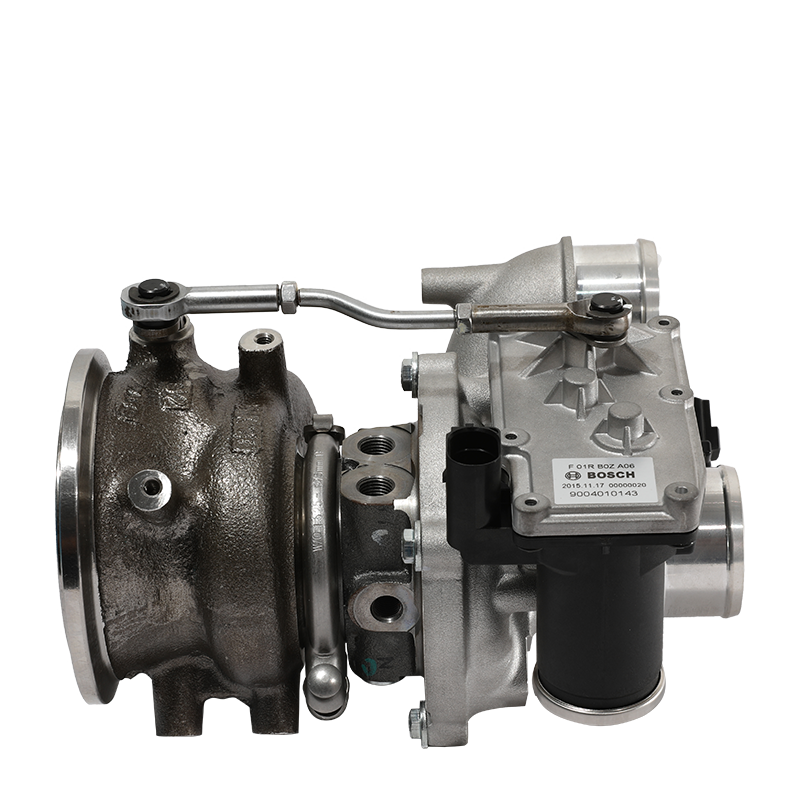

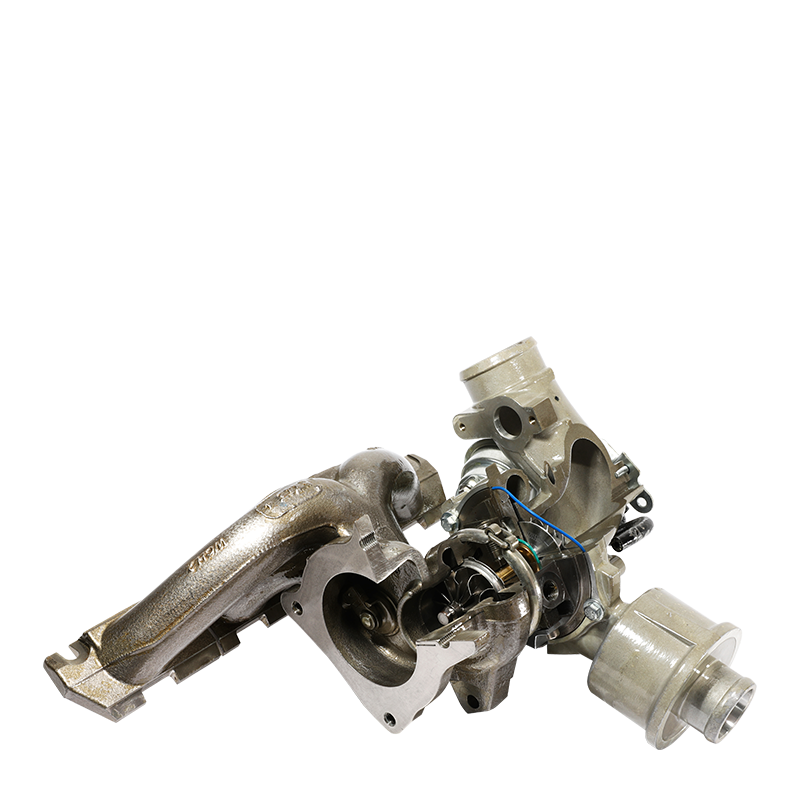

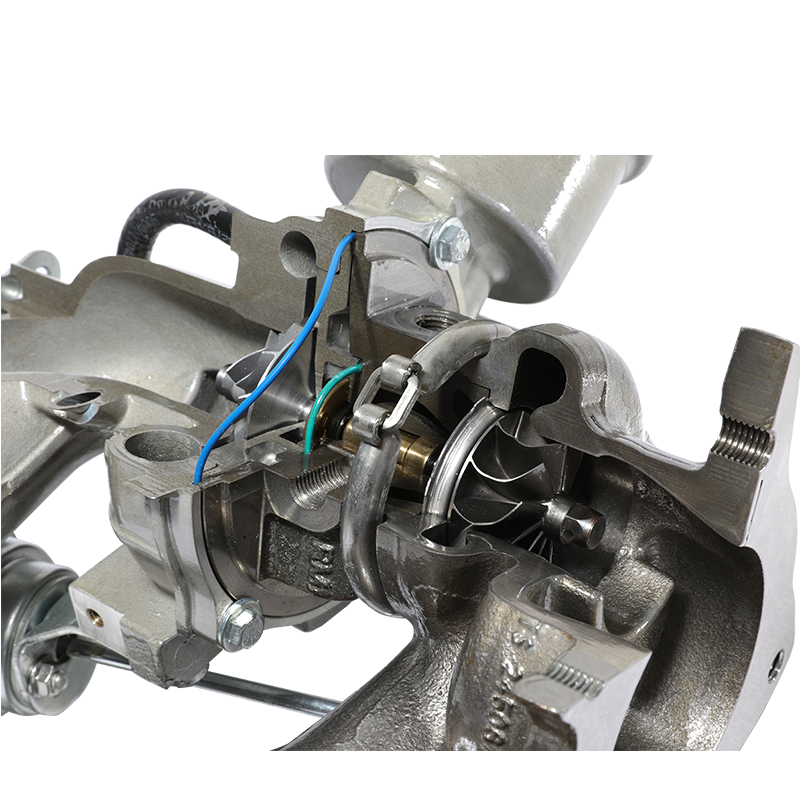

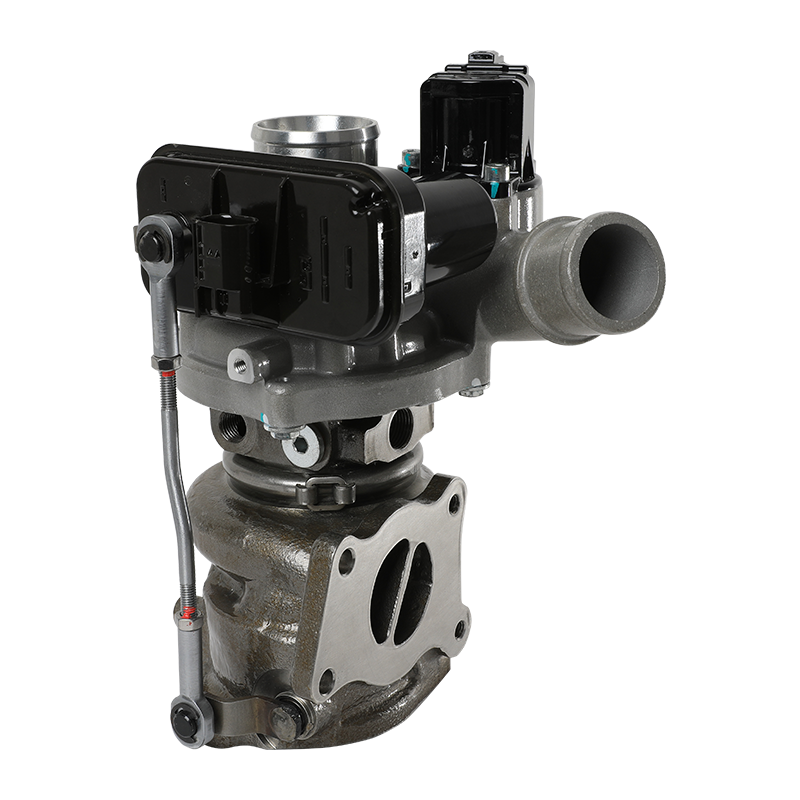

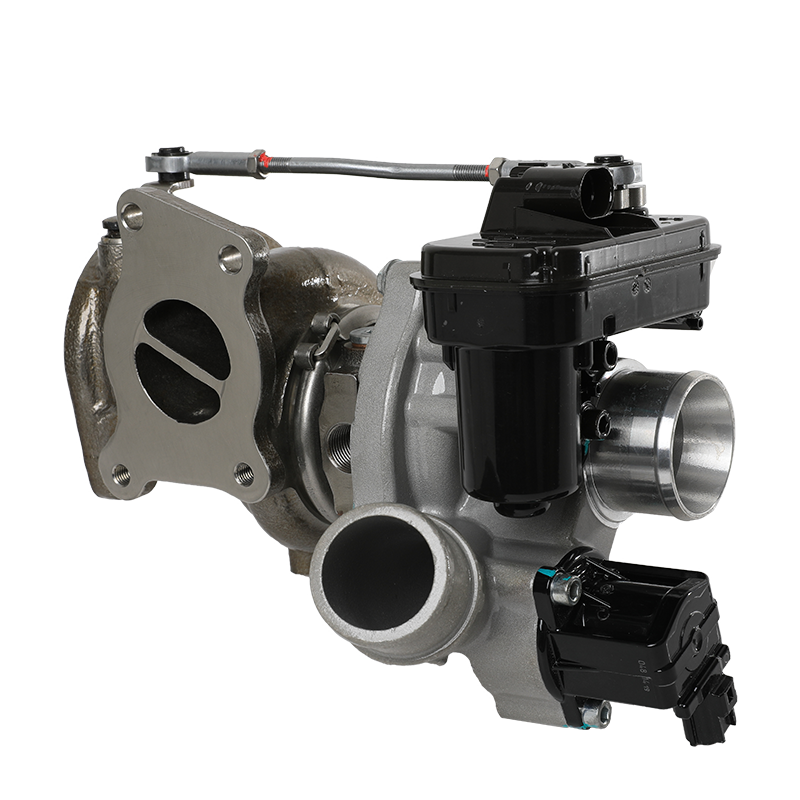

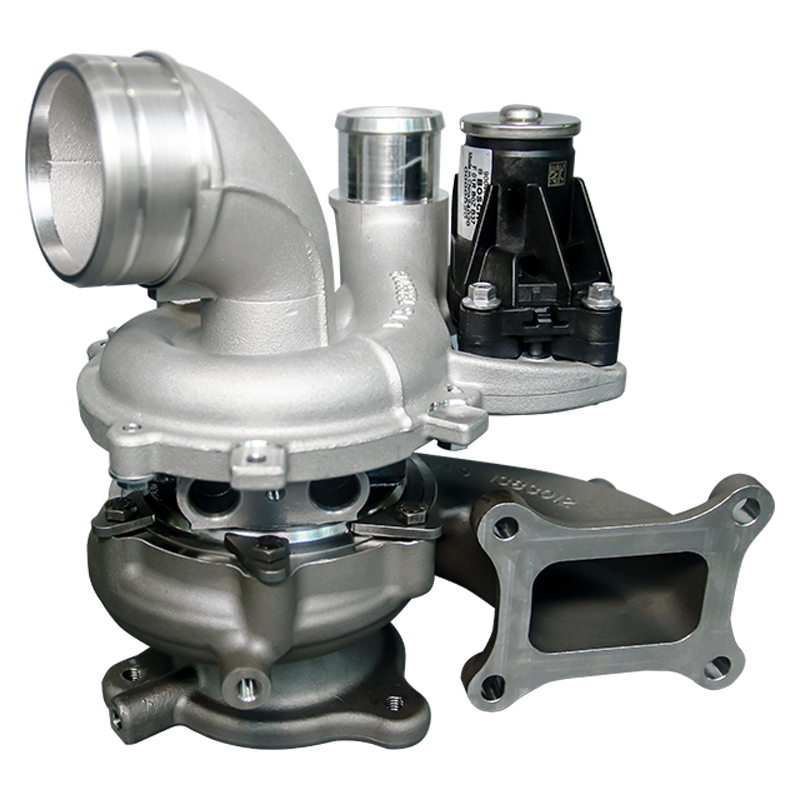

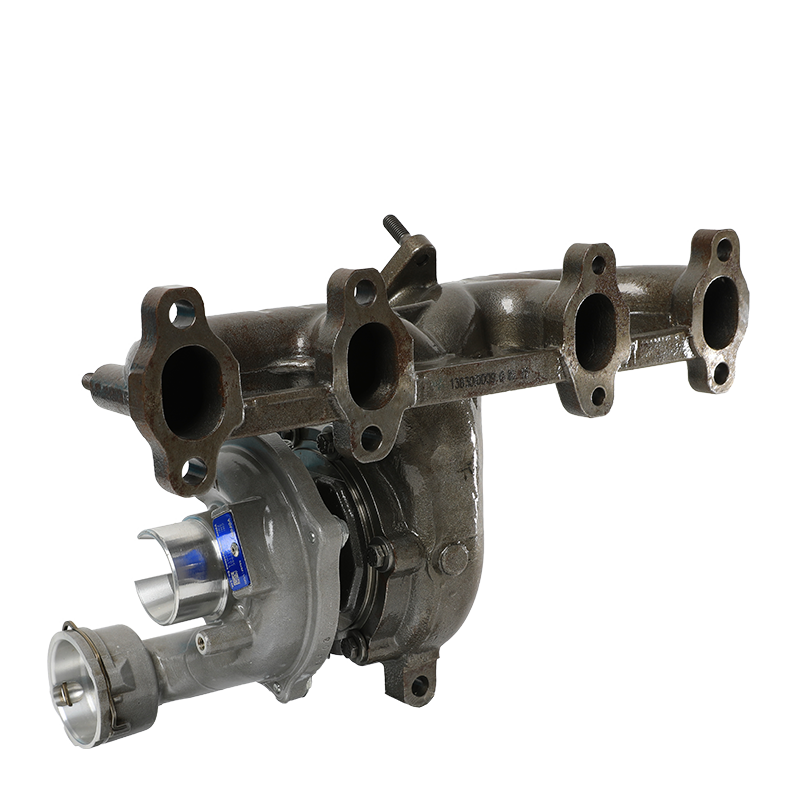

VTG

Improve acceleration performance by 25%

Increase engine low-speed torque

Support Miller cycle, support four-stage fuel consumption regulations

Electric actuator and mechanical actuator are optional

Can meet Max930℃

It can meet the application requirements of 1.0L~1.8L (95kw~120kw) engines

Improve acceleration performance by 25%

Increase engine low-speed torque

Support Miller cycle, support four-stage fuel consumption regulations

Electric actuator and mechanical actuator are optional

Can meet Max930℃

It can meet the application requirements of 1.0L~1.8L (95kw~120kw) engines

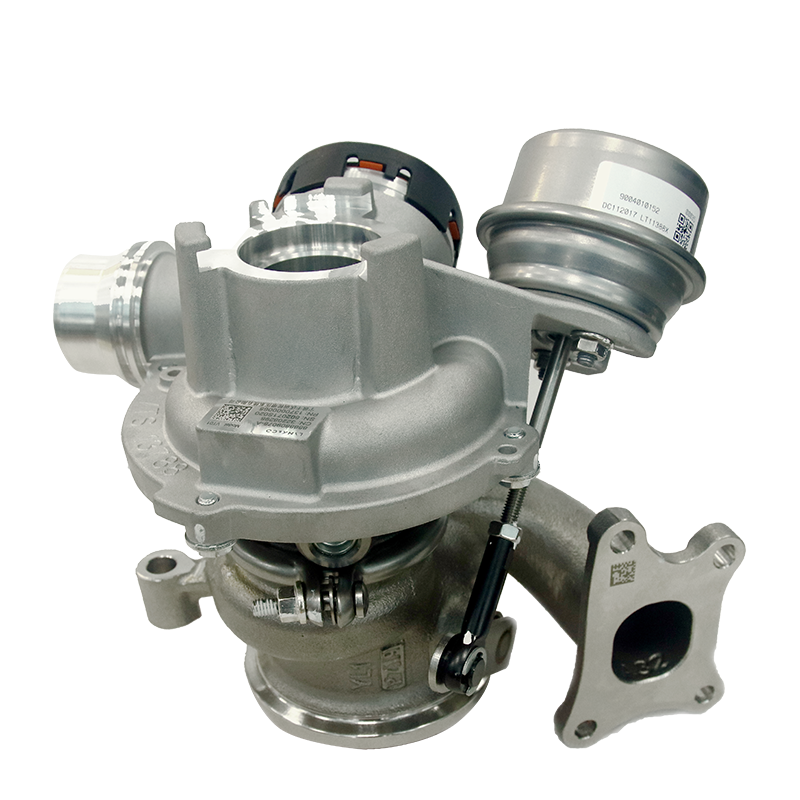

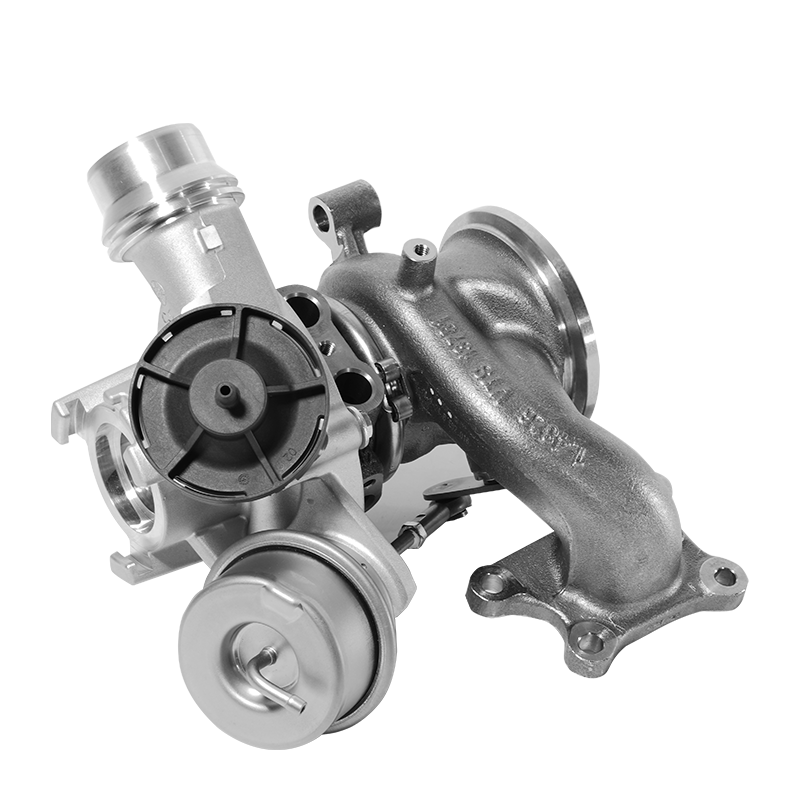

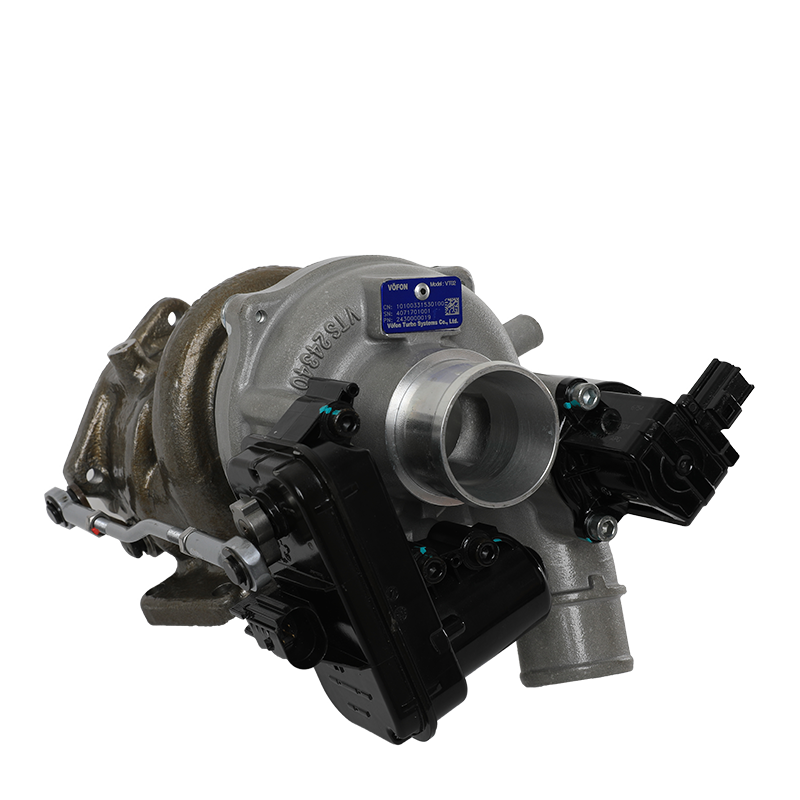

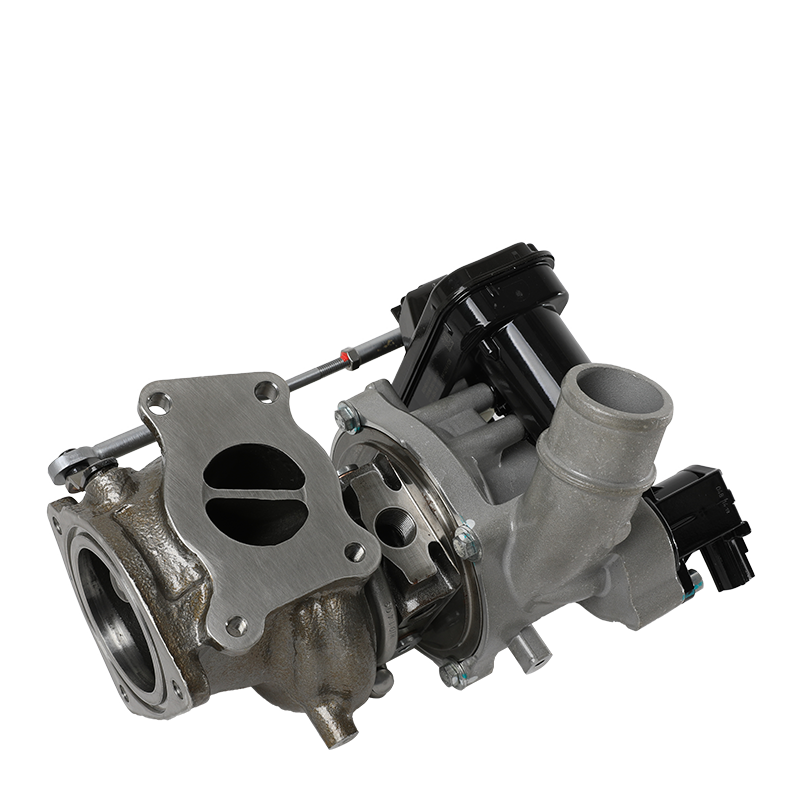

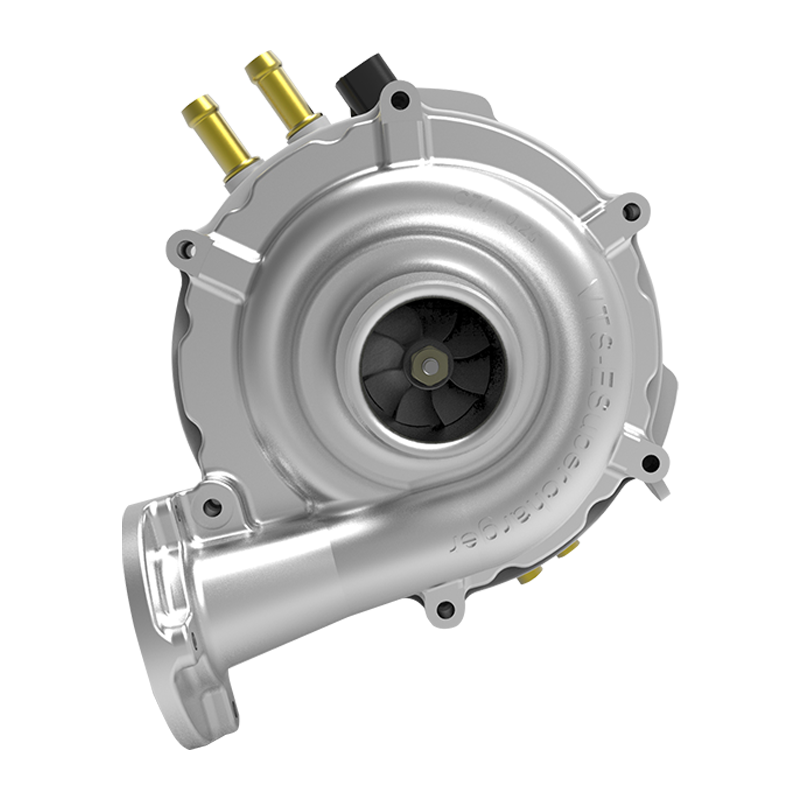

Electric Supercharger

Transient response improved by more than 30%

Increase engine low-speed torque by 20%~50%

Working in conjunction with a turbocharger, the power per liter can be much higher than 100kw

Miniaturization and lower rotation speed of the engine

Significant further reduction of CO2 emissions

Driven by a motor, the motor efficiency can reach 92%, and the electric control efficiency can reach 98%